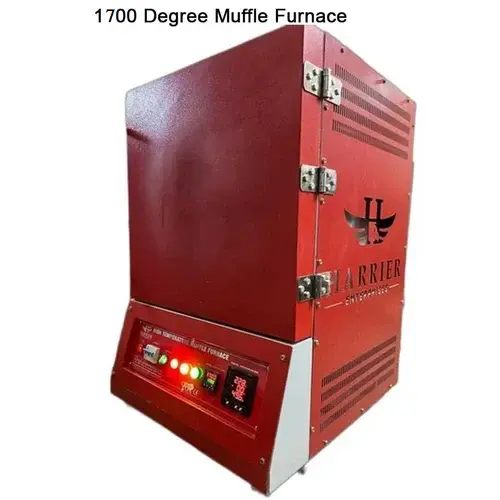

Application of High Temperature Muffle Furnace 1700°C :

1700°C High Temp Muffle Furnace (Box Type Resistance Furnace) Mainly Provides High Temperature Heat Treatment Environment For Industrial Colleges, Research Institutes, Factories and Other Industrial Laboratories, And Is Applied To New Materials Such As Metal Materials, Ceramic Materials, Nano Materials, And Semiconductor Materials.

A high-temperature muffle furnace is a specialized heating device used in laboratories and industrial settings to achieve extremely high temperatures for various purposes such as material testing, heat treatment, ashing, and ceramic or glass production.

Features of high-temperature muffle furnace:-

Construction and Design: The furnace is typically made of high-quality, heat-resistant materials such as refractory bricks, ceramic fiber insulation, and high-temperature alloys to withstand extreme temperatures.

Heating Element: High-temperature muffle furnaces use heating elements made of materials like Kanthal, silicon carbide, or molybdenum disilicide.

Temperature Control and Regulation: The furnace is equipped with precise temperature control systems, often utilizing digital controllers.

Safety Features: Safety measures such as over-temperature protection, temperature alarms, and automatic shut-off systems are integrated to prevent overheating and ensure safe operation.

Product Specification

| Model | HE-MF-1700p |

| Maximum Temp | 1700°C |

| Working Temp | 1600°C |

| Temp Accuracy | 1°C |

| Heating Elements | Molybdenum Disilicide Heating Element Easily Replaced (MoSi2) |

| Power Supply | 220 / 415 Volts 3 phases And Single Phase AC Supply |

Enquiry Now

Type | Benchtop |

Furnace Structure | Chamber Material, Temperature Controller System, Heating Element, Furnace Shell And Other Assistant Parts |

Max Temperature | 1700℃ |

Continue Operating Temp. | 1600℃ |

Heating Element | High Quality Molybdenum Disilicide (MoSi2 ) heater |

Chamber Material | High Temperature1800 Grade Ceramic Fiber Material |

Temperature Accuracy | ±1℃ |

Thermocouple | B Type |

Temperature Controller | Ø PID automatic control via SSR power control with phase angle fired, current limiting resistor. Ø 1 programmable x 16 segments for precise control of heating rate, cooling rate and dwell time. Ø Built in PID Auto-Tune function with overheating & broken thermocouple broken protection for this Muffle Furnace 1400 type. Ø Over temperature protection and alarm allows for operation without attendant. |

Electronic Component | Autonics / Schneider / L&T Electronics Brands |

Heating Rate | ≤ 15℃/Min (Suggest 10℃/Min For Longer Life Using of Furnace) |

Safety Protection | Overheat And Thermocouple-Break Alarm |

Certification | NSIC REGD, ISO 9001 – 2015/14001-2015/13485-2016/FDA/ GMP/CE CERTIFIED |

Furnace Shell | High Quality GI Sheet With PP Powder Coated |

Insulation | High Quality Ceramic Fiber Zirconia Grade Thermal Insulation Material To Ensure A Good Uniformity |

Accessories | Ø One Pair of High Temperature Furnace Gloves |

Using Attentions | Ø The cooling rate for this Muffle Furnace 1700 type shall also not exceed 10℃ /min. Ø Toxic or explosive gases are not |

Frequently Asked Questions (FAQ)

What is a high-temperature muffle furnace?

A high-temperature muffle furnace is a specialized heating device designed to reach and maintain high temperatures within a controlled environment. It’s commonly used in laboratories and industrial settings for processes like sintering, calcination, and heat treatment of materials.

How does a muffle furnace work?

A muffle furnace works by heating a heating element (often made of resistant materials like Kanthal) to generate intense heat. The heating element is enclosed in a chamber called the muffle, which provides insulation and maintains the desired temperature. The material to be heated is placed inside the muffle, and the furnace is programmed to reach and maintain the required temperature.

What are the typical operating temperatures of a high-temperature muffle furnace?

High-temperature muffle furnaces can reach temperatures ranging from 1000°C to 1800°C (1832°F to 3272°F) and sometimes even higher, depending on the model and design. The temperature range varies based on the specific furnace and its intended applications.

What are the applications of a high-temperature muffle furnace?

High-temperature muffle furnaces find applications in various fields, including materials science, ceramics, metallurgy, pharmaceuticals, and research. They’re used for processes such as annealing, ashing, sintering, roasting, and heat treatment of materials.

What types of materials can be processed in a high-temperature muffle furnace?

Materials like metals, ceramics, glass, and other heat-resistant substances can be processed in a high-temperature muffle furnace. These furnaces are especially useful for processing materials that require high-temperature treatments for transformation or modification.

What safety precautions should be taken when operating a high-temperature muffle furnace?

Safety precautions include using appropriate personal protective equipment (PPE) like heat-resistant gloves, safety goggles, and lab coats. Ensure proper ventilation, follow manufacturer instructions, and be cautious when handling hot materials or opening the furnace after a heating cycle.

How do I choose the right high-temperature muffle furnace for my application?

Consider factors such as the required temperature range, chamber size, heating rate, control options (e.g., programmable controllers), and the types of materials you’ll be working with. Consulting with a furnace supplier or an expert can help tailor the selection to your specific needs.

Can a muffle furnace be used for both research and industrial applications?

Yes, muffle furnaces are versatile and can be used in both research and industrial settings. They are widely utilized in laboratories for research purposes and in industrial settings for large-scale material processing and production.